Quality Audit

MSCE rendering reliable services of Non Destructive Testing, Construction Material Laboratory Testing, Concrete Quality Control and Audit.

Proficient Workforce

We MSCE are proud of the fact that we have recruited a team of highly experienced personnel, who have aided us to sustain our distinct place in this competitive market. All our team members work in a close coordination with each other in order to meet with the client's requirements. These team personnel are committed to provide qualitative services through their sheer commitment to the work.

Our Strength

The high quality standards of our service range to our customers. Some other core factors that have contributed towards strengthening our position are as follows:

- Most Reliable Results

- Accuracy

- High Technical Competency

- All Services under one roof

- Rendered by skilled professionals

- Rendered as per the set industry norms

- Quality raw materials used

Audit & Certification

Audits are one of the main tools for monitoring the performance of the Quality Management System of a construction project but they are overlooked sometimes. There are cases that the audits are used by the management not as a proactive (or performance monitoring) measure but as an investigation tool when something is already wrong…

We are engaged in rendering credible services for Structural Stability Certification to our esteem patrons. As per the Government regulations, diverse Factories and Residential Societies are expected in order to undergo assessment and obtain a Structural Stability Certificate from a chartered civil engineer in every five years. Our firm has emerged as a competent authority that provides reliable Structural Stability Certification Services. These services include detailed inspection, assessing the strengths & weakness of the structure, conducting NDT, preparing repair / rehabilitation scheme, monitoring repair work and thereafter issuing Structural Stability Certificate.

Quality Control and Audit

Backing on the sincere efforts made by our professionals, MSCE render credible facilities of Concrete Quality Control and Audit to our clients. Our enterprise has a credible Quality Control & Auditing Scheme for the RCC structures. The Total Quality Solution is provided by our firm for concreting activity, which includes Testing of all building material out sources, monitoring concrete quality with NDT.

Third Party Audits

This is when a third party accredited organization is invited to audit a construction project in order to

- The monitors the project's system and performance

- To perform audits during the production of the “product”.

- To give the ISO:9001 Certification

Quality & Safety

Objective

- Awareness of quality & safety practices and need for quality in construction

- Establish planned quality & safety as a widely accepted practice for construction sites

- Bring best of practices in industry to easily practicable form

- Quality Assurance and compliance with Third part Quality

- Work Specification, authorize deviations from specifications.

- Preparation of project Specific Quality Assurance (QA) and Safety Assurance (SA) policies and procedures

- MSCE shall coordinate with the separate safety specialist if appointed by the clients

Approach

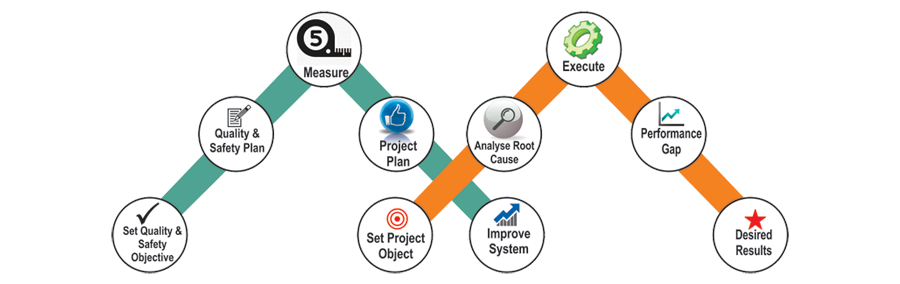

Our approach as captured in "M" model shown above focuses on:

- "Based on the Plan-Do-Check-Act-Improve cycle, this system ensures Action Learning by the organization audited and provides lasting improvements."

- Planning quality & safety alongside the project at each major stage of the project

- Ensure quality & safety is given due recognition and is built in to the system ab initio

- Pre-setting quality & safety benchmarks for specifications, work performance and workmanship requirements

- Monitoring work against these matrixes

- Reporting holistically on preventive action, corrective action and innovative practices

- Recommending changes based on the root cause analysis of vital issues

- Protectively aim at preventive care rather than finding a cure

Engagement Matrix

The various engagement models envisaged are :

- Comprehensive service across project life cycle

- Quality & Safety Planning matrix identification

- Reporting on preventive, corrective and innovative actions

- Root cause analysis and recommendations for systemic improvements

- Conducting pre-delivery inspections

- Providing Quality & Safety Planning and Operating Procedure tailoring prior to execution

- Conducting Quality & audits

- Conducting Pre-delivery inspections